21 Scientific Patents Driving the Future of Rare Gas Purification

Guest Contribution – Rare gases used to be niche materials – scientific curiosities, specialty industrial inputs, things most people never thought about. That’s no longer the case. Today, neon drives semiconductor manufacturing, helium stabilizes advanced imaging and aerospace systems, and xenon plays a growing role in lighting, propulsion, and medical technology. As industries demand tighter tolerances and cleaner performance, purity standards have moved from “high” to “extreme.”

Modern purification isn’t just about filtering contaminants. It’s about precision control at cryogenic temperatures, molecular-level separation, and energy efficiency under industrial pressure. This is where the latest wave of patents becomes more than paperwork – they represent the engineering backbone of ultra-high purity innovation.

Much of this acceleration has been shaped by organizations pushing cryogenic boundaries – including Cryoin Engineering – whose work highlights how deeply integrated cryogenic science has become with rare gas purification. The next generation of patents reflects that shift: smarter systems, tighter tolerances, and architectures built for scalability rather than isolated lab success.

What follows isn’t just a list of inventions – it’s a snapshot of how cryogenic patents for neon, helium, and xenon, including cryoin 21 patents rare gas purification innovations, are redefining industrial purity standards.

Advanced cryogenic fractional separation systems

This patent introduces a refined approach to cryogenic fractional separation, allowing gases with extremely close boiling points to be isolated with higher precision. Traditional separation columns struggle with trace overlap, especially when scaling production. The new architecture integrates staged cooling gradients and micro-flow balancing to reduce contamination drift.

The result is improved yield without sacrificing purity – a key requirement for semiconductor-grade neon production. By stabilizing thermal transitions, the system minimizes energy spikes while maintaining consistent separation accuracy.

Ultra-high purity neon refinement architecture

Neon purification presents a unique challenge: even microscopic impurities can disrupt downstream processes. This patent outlines a layered refinement structure combining cryogenic condensation with targeted adsorption chambers.

Instead of relying on single-stage filtration, the system dynamically adjusts flow paths based on impurity readings. Sensors feed real-time data into a control module that modifies temperature and pressure conditions mid-cycle. This responsive design reduces waste and improves consistency – an essential factor in ultra high purity innovations.

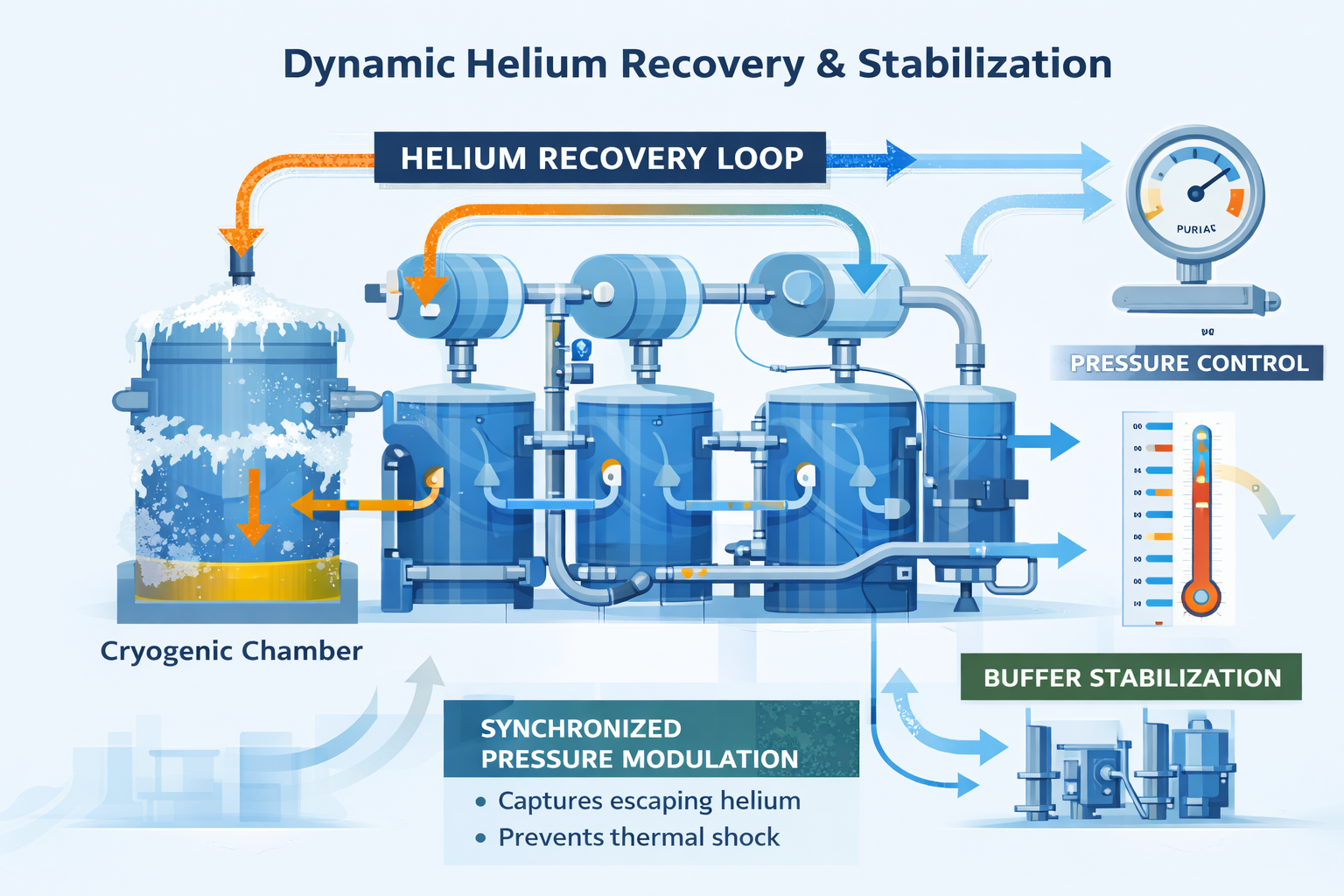

Dynamic helium recovery and stabilization loops

Helium’s low density and escape tendency make recovery notoriously inefficient. This patent proposes a closed stabilization loop that captures helium during transitional phases, preventing loss while maintaining cryogenic equilibrium.

The innovation lies in synchronized pressure modulation: helium is cycled through micro-stages that preserve purity while reducing thermal shock. Industrial facilities benefit from higher retention rates and lower operational cost – without compromising purity thresholds.

Xenon micro-contaminant removal platforms

Xenon applications demand exceptional cleanliness, especially in aerospace and medical imaging. This system targets ultra-trace contaminants using cryogenic trapping combined with molecular sieve refinement.

Unlike conventional filters, the platform isolates impurities by phase behavior rather than mechanical obstruction. This reduces filter fatigue and extends operational lifespan while maintaining tight purity tolerances.

Hybrid cryogenic adsorption chambers

This patent merges cryogenic condensation with adsorption materials engineered for rare gas compatibility. The chamber architecture allows gases to transition through temperature zones optimized for impurity capture without interrupting flow continuity.

The hybrid approach increases throughput while lowering energy requirements – a significant improvement over purely mechanical or purely thermal purification systems.

Precision thermal gradient purification control

In cryogenic separation, temperature control isn’t a background detail-it’s the whole game. Even tiny fluctuations can throw off separation accuracy. This patent tackles that problem with a feedback-driven thermal mapping system that continuously adjusts cooling profiles in real time.

Sensors track micro-level temperature shifts and correct them before they have a chance to affect purity. The result is smoother operation, less thermal stress on equipment, and far more consistent outcomes. For large-scale purification cycles, that kind of repeatability isn’t just nice to have-it’s essential.

Multi-stage rare gas recirculation systems

Instead of treating purification as a straight, one-way path, this design loops gases back through the system until the required purity is actually reached. Each stage in the loop targets a different class of contaminants, improving overall efficiency without piling on unnecessary complexity.

The modular structure makes the system easy to scale, which is a big advantage for industrial facilities dealing with fluctuating gas volumes. As demand shifts, the process can adapt-without forcing a full redesign every time conditions change.

Smart impurity detection and auto-correction modules

Real-time monitoring is central to modern purification. This patent integrates spectral analysis sensors with automated correction routines that adjust cryogenic conditions instantly when impurity thresholds are detected.

The system reduces downtime and prevents batch contamination, making purification cycles more predictable.

Energy-optimized cryogenic compression cycles

Cryogenic purification is energy intensive. This innovation redesigns compression sequencing to recover thermal energy between stages. By recycling cooling potential, the system reduces overall power consumption while maintaining separation efficiency.

Energy optimization becomes particularly important in continuous industrial operation.

High-efficiency rare gas condensation sequencing

The final patent in this segment focuses on condensation timing. Precise sequencing ensures gases enter cryogenic phases at optimal intervals, preventing cross-contamination and maximizing yield.

Improved cycle coordination reduces mechanical strain and enhances long-term system stability – a subtle but meaningful gain in industrial environments.

Closed-loop ultra-clean neon refinement

Where earlier neon systems relied on linear pass-through purification, this patent introduces a closed-loop architecture that keeps neon circulating until ultra-trace impurity thresholds are met – and verified. The clever part isn’t just the loop; it’s the validation logic layered into it.

Each cycle includes micro-sampling checkpoints that confirm purity in real time, preventing premature discharge. This reduces waste while tightening quality control. For semiconductor applications – where neon purity isn’t negotiable – this system provides consistency without slowing throughput. It’s purification with built-in skepticism: the gas isn’t considered clean until it proves it repeatedly.

Low-loss helium cryo-capture arrays

Helium has a habit of escaping exactly when you don’t want it to. Traditional capture systems accept a degree of loss as unavoidable. This patent challenges that assumption with a cryogenic array designed to intercept helium at transitional pressure zones.

Instead of relying on brute-force containment, the system leverages temperature gradients that naturally guide helium into capture chambers. Loss rates drop. Thermal shock decreases. Operational efficiency rises. Facilities handling high volumes of helium gain stability without increasing mechanical complexity – a rare win in cryogenic engineering.

Xenon stabilization filtration frameworks

Xenon purification faces a unique issue: maintaining molecular stability during aggressive filtering. This framework introduces staged stabilization zones that cushion xenon as it transitions through cryogenic filtration.

By controlling pressure and temperature fluctuations with precision timing, the system prevents destabilization that could otherwise introduce microscopic contamination. The result is cleaner xenon with fewer stress-induced anomalies – especially important in aerospace propulsion and advanced imaging environments. This approach reflects the broader evolution seen in cryogenic patents neon helium xenon systems, where stability engineering directly elevates rare-gas purity and performance standards.

Modular cryogenic purification stacks

Scalability has always been a bottleneck in rare gas purification. Large systems demand enormous upfront investment; small systems struggle with throughput. This patent proposes modular cryogenic stacks that can be expanded incrementally.

Each module operates as a self-contained purification unit while synchronizing with neighboring stacks. Facilities can grow capacity without redesigning entire infrastructures. Maintenance becomes easier too – modules can be serviced independently, minimizing downtime.

Micro-scale contaminant targeting technology

Some impurities exist in concentrations so low they’re practically invisible – until they disrupt sensitive applications. This patent introduces micro-targeting chambers that isolate contaminant behavior at cryogenic temperatures.

Instead of broad filtration, the system identifies specific impurity signatures and applies tailored removal strategies. Precision improves. Waste decreases. The purification process becomes less about volume and more about accuracy – a critical shift for ultra-clean industrial environments.

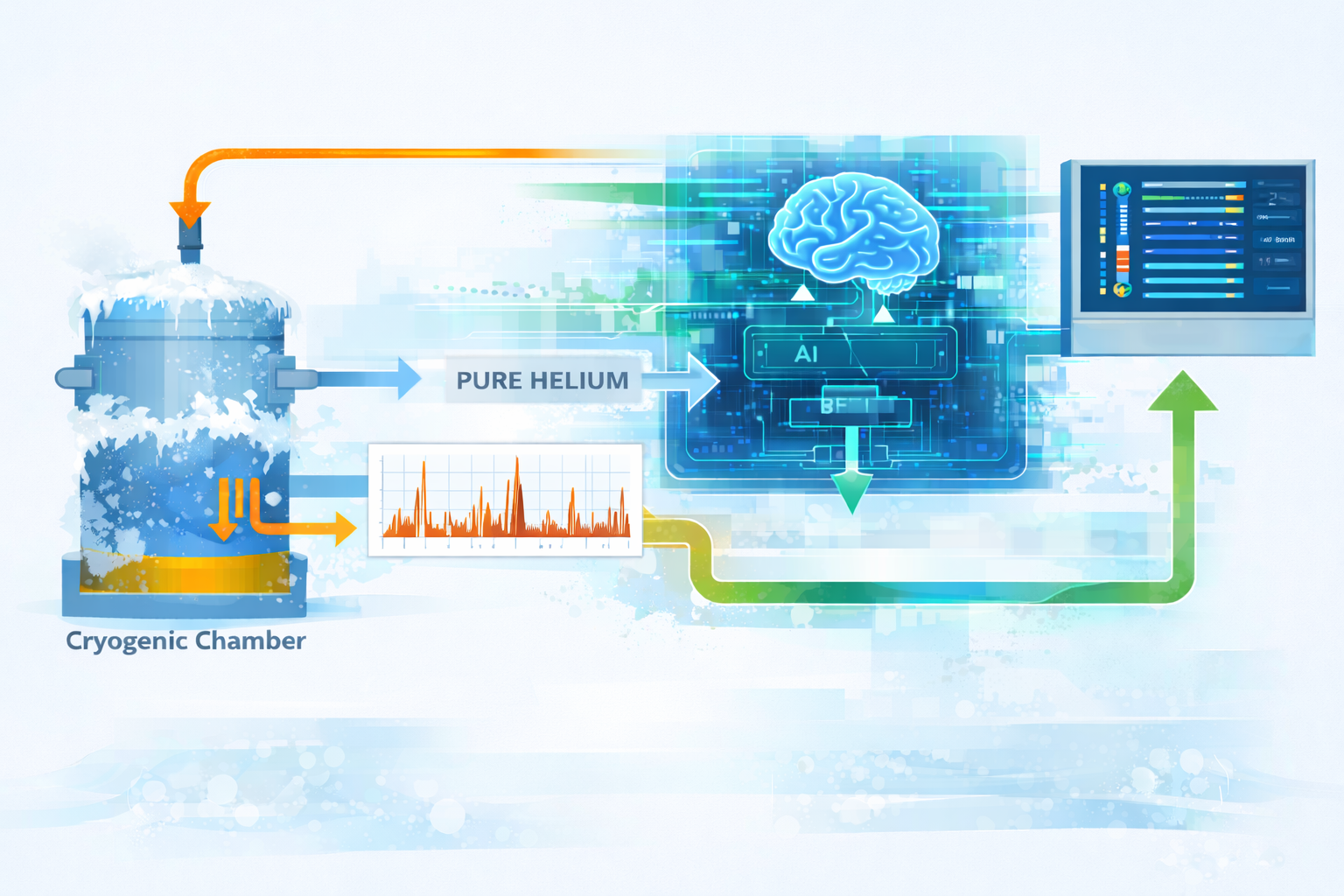

AI-assisted purity balancing systems

Automation isn’t new to cryogenics, but this patent integrates predictive modeling directly into purification control. Sensors feed impurity data into an AI module that forecasts contamination trends and adjusts system parameters proactively.

Rather than reacting to deviations, the system anticipates them. Temperature gradients shift subtly. Pressure balances correct themselves before thresholds are crossed. This predictive behavior reduces cycle interruptions and increases consistency, especially in facilities running continuous purification operations.

High-density cryogenic storage purification

Storage isn’t supposed to be passive-or at least, this patent argues it shouldn’t be. Instead of treating storage as a holding pattern, the system builds purification logic directly into high-density cryogenic tanks. Gases are continuously monitored and gently reconditioned while they sit, preventing slow purity drift that usually goes unnoticed until it’s too late.

The payoff is subtle but important. Less need for cleanup after storage. Fewer surprises when gases are finally used. For industries that depend on ultra-clean gases staying that way for long stretches of time, this approach finally bridges the gap between purification and long-term preservation.

Adaptive gas phase separation networks

Most separation systems follow a fixed script. Same steps, same order, every time. This patent breaks that habit.

Instead, it introduces adaptive separation networks that respond to live impurity data. If the contaminant profile shifts mid-cycle, the system doesn’t push through blindly. It reroutes gas flow through alternate cryogenic zones better suited to the new conditions. The result: fewer rejected batches and higher overall yield-especially in environments where feedstock composition refuses to stay consistent.

Ultra-trace impurity neutralization methods

At extremely low concentrations, impurities stop behaving predictably. Traditional removal methods don’t always work-and sometimes make things worse. This patent takes a different angle.

Rather than trying to trap these contaminants outright, the system stabilizes them first. Chemical neutralization micro-zones operate alongside precise temperature controls, reshaping how impurities behave so they can be captured without disrupting cryogenic balance. It’s a quiet shift in philosophy: instead of fighting contaminants head-on, the system changes the rules they operate under.

Industrial rare gas recycling platforms

Recycling rare gases sounds efficient-until contamination sneaks back in. Historically, that’s been the trade-off. This platform redesigns the recycling loop from the ground up.

Integrated cryogenic checkpoints verify purity before recycled gas is reintroduced into the system. Sensors and micro-condensation stages act as constant safeguards, ensuring recycled streams meet the same standards as freshly purified gas. The result is less waste without sacrificing quality – a balance older systems struggled to achieve.

Integrated cryogenic purity ecosystems

The final patent zooms out. Way out.

Instead of improving individual components, it treats purification, storage, monitoring, and recycling as parts of one connected cryogenic ecosystem. Data moves freely between modules. Decisions are coordinated. The system behaves less like a collection of machines and more like a single, intelligent infrastructure.

Efficiency goes up. Performance becomes predictable. Maintenance shifts from reactive fixes to proactive management.

And that’s the bigger signal here. Purification is no longer just a step in the process – it’s becoming an environment.

________________________________________________________________________________________________________________

Advertisements placed in our Guest Contribution sections are in no way intended as endorsements of the advertised products, services, or related advertiser claims by NewsroomPanama.com, the website’s owners, affiliated societies, or the editors. Read more here.