The Effects of US Tariffs are Beginning to take their Toll on Chinese Industries & Panama Canal

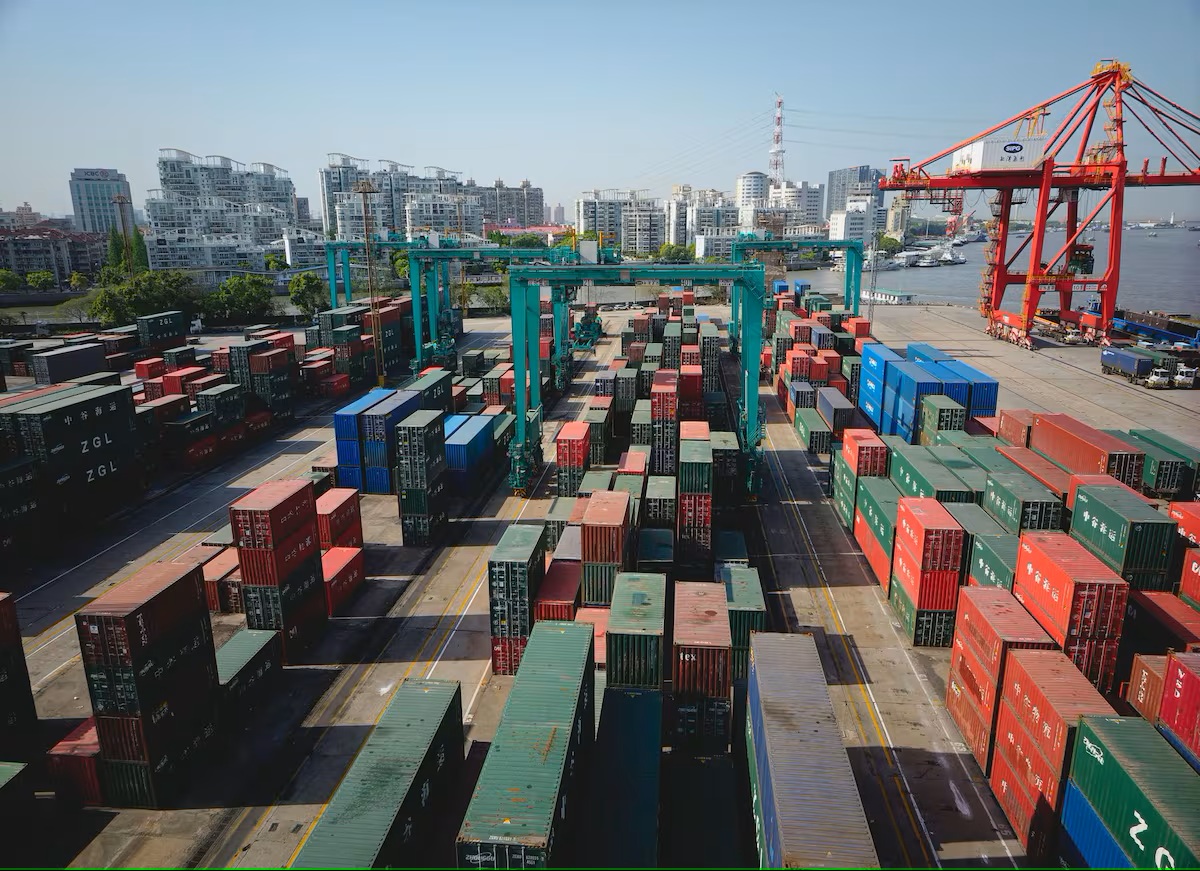

An aerial photograph shows the Shanghai Container Terminal in Shanghai, China.

The effects of US tariffs are beginning to take their toll on Chinese industries, with production cuts, layoffs, and even the mid-ship abandonment of containers already sailing toward the United States before or after passing through the Panama Canal. The most extreme case is the abandonment of cargo that had already been chartered for the United States, which companies are giving away to shipping companies or transport firms to avoid paying the taxes they would have to pay to import it into the United States. Chinese manufacturers across a wide range of sectors – from petrochemicals to printed mugs – have been quietly but rapidly moving to set up new American facilities in recent weeks, as they try to dodge the worst effects of an intensifying US-China trade war. Chinese exporters in a slew of industries are setting up US facilities to escape crippling tariffs – but doing so is often far from easy.

Chinese Firms Race to Open US Factories to Avoid Sky-High Tariffs as Trump’s Tariff War Hits Home

For weeks, Ryan Zhou has been running on little sleep. The 38-year-old entrepreneur from eastern China has been pulling 14-hour shifts, trying to open his company’s first factory in Dallas before the summer heat rolls in. It’s a race against time — and tariffs. Zhou’s business, which makes custom-printed mugs and T-shirts, once thrived by shipping thousands of small parcels to the US every day. But everything changed after US President Donald Trump ramped up tariffs on Chinese imports, slapping a 145 per cent duty on a vast range of goods. Beijing hit back with 125 per cent tariffs of its own. “The United States is 95 per cent of our market,” Zhou said, as reported by South China Morning Post. “We can’t afford to lose it.” For Chinese exporters like Zhou, the message was clear: move production to America, or risk being priced out of the market.

Tariff War Reaches Boiling Point

Since returning to office in January, US President Donald Trump has imposed sweeping tariff hikes on Chinese goods, raising duties by an average of 145 per cent. In response, Beijing retaliated with 125 per cent tariffs on US imports, deepening the standoff between the world’s two largest economies. According to the Peterson Institute for International Economics, the tariff increases are some of the most aggressive since the 1930s and have already started reshaping global supply chains. For Zhou’s business — which makes custom-printed mugs and T-shirts — the impact was doubly severe. Not only did the new tariffs target a broad range of consumer goods, but Washington also scrapped the “de minimis” rule, which had previously allowed low-value shipments to enter the US tax-free. Now, each small parcel faces a 90 per cent levy, severely undermining his cost structure.

Setting up Shop in America

According to the South China Morning Post report, Zhou’s Dallas plant, scheduled to open in May, will handle only the simplest production steps. “Labor costs here are much higher, and regulations are strict,” he said. “In China, a single product might pass through ten stages. In Dallas, we’ll do just one or two.” Other Chinese businesses are rushing to make similar moves. Zhu Ning, who runs a consultancy that helps companies localize production in the US, said he has been swamped with inquiries. “Automation is key,” Zhu said. “American wages are high, and honestly, worker efficiency doesn’t always match what you find in China.”

Leo Li, a Shenzhen-based electronics manufacturer, just opened a 1,000-square-metre plant in Reno, Nevada. His new facility focuses on assembling sensor modules — a simpler, less labour-intensive process. However, it’s not a perfect solution. Sourcing materials in the US remains difficult and costly. “The supply chain here just isn’t as complete,” Li said. But like Zhou, he believes that moving closer to customers is worth the trouble. “Our costs will rise, but not as much as they would with the tariffs,” Li said. “The goal is to survive — and stay competitive.”

China Fights Back Against US Tariffs

While factories move west, Beijing is also flexing its muscles in another area: rare earth minerals. China imposed export controls on gallium, germanium, and other essential materials for industries like semiconductors and green energy. According to a Reuters report, this has rattled US manufacturers, who are scrambling to secure alternative supplies from allies like Australia and Canada. China described the move as a “necessary countermeasure” to what it calls US economic bullying, raising fears that the trade war could spill over into a broader tech conflict.

What Next?

Despite the rocky landscape, many Chinese entrepreneurs remain committed to the US market. “As long as the US dollar stays dominant, America will stay the world’s biggest consumer market,” Zhou said. Experts predict a growing wave of Chinese investment in US-based manufacturing, especially in sectors like petrochemicals, where raw materials were once shipped to China for processing. Ye Yingmin, founder of Beijing’s Chem1 consultancy, told South China Morning Post that the old model no longer makes sense with high tariffs on both ends.

“We’re seeing Chinese firms preparing to invest heavily in places like Texas,” Ye said. His firm itself is opening its first overseas office in Houston. Meanwhile, there are whispers of a possible de-escalation. Trump recently admitted that the current tariff levels are “unsustainable”, and officials have hinted at potential talks. However, China has dismissed these reports as “fake news”, and no formal negotiations have been announced. For Zhou, it doesn’t change the game plan. “We were already planning to come here,” he said. “The trade war just made us move faster. Now, we’re here to stay.”